Infrared (IR) technology is widely used in the oil and gas industry as an inspection tool for condition monitoring and predictive maintenance. It is advantageous over traditional visual inspection and other tools because infrared technology does not have to be in contact with the equipment being monitored.

IR thermography is a form of nondestructive testing that measures temperature variances of a component as heat (i.e. thermal radiation) flows through, from, or to that component. IR thermography is also generically known as IR testing, thermal testing, thermal imaging, and IR thermometry.

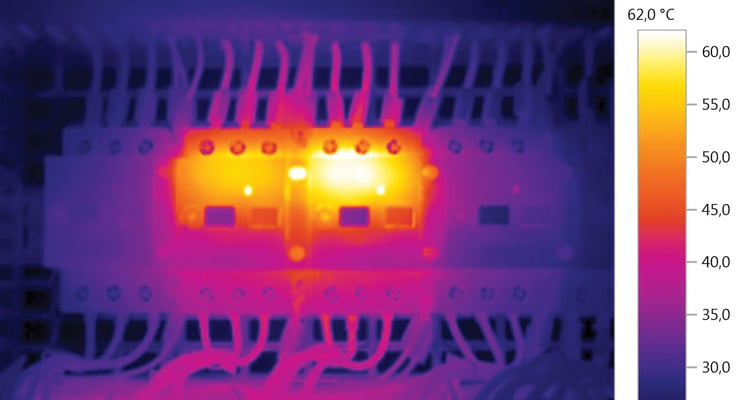

Thermal radiation is directly related to changes in temperature. In other words, as a component changes temperature, the amount of radiation emitted changes. Since this type of radiation is a form of electromagnetic waves that cannot be seen with the human eye, components have to be analyzed using infrared cameras. Infrared cameras are able to detect and display emitted, reflected, and transmitted infrared energy from an component. The thermal image can then be analyzed to obtain a temperature reading for the component.

The purpose of mapping temperature levels and variances of a component is to detect any hot spots where equipment may weaken or fail. IR thermography is also capable of detecting corrosion damage, delamination, voids, inclusions, and other flaws that affect heat transfer. However, in order to detect these anomalies, there must be sufficient temperature difference between the component and its surroundings.

Fundamental IR Thermography Concepts

Emissivity refers to a material’s ability to emit infrared energy. Emissivity is expressed as a value between 0 and 1 where 0 describes a perfect mirror surface and 1 describes a blackbody. For example, a material with an emissivity value of 0.95 absorbs and emits 95% of infrared radiation and reflects 5% of the surrounding radiation.

Reflectance refers to the amount of light reflected from the surface of a material.

Transmittance is a material’s ability to transmit thermal energy (i.e. heat) from a component being tested to an infrared camera. For example, plastics are transmissive while metals are opaque and are not transmissive.

Heat vs Temperature

These terms are commonly used interchangeably. Although they are related, they have very distinct meanings.

- Heat is a measure of the total energy of molecular motion of an object and is dependant on the size of the object. Heat also describes how thermal energy transfers from one object to another or its surroundings.

- Temperature refers to an object’s average energy of molecular motion and, unlike heat, can be measured directly. Temperature does not depend on the size of the object.

Infrared is an invisible portion of the light spectrum. All objects warmer than absolute zero will emit energy within the spectrum.

The warmer the object, the brighter we see in an infrared thermal imager. With thermography, a problem can be observed without dismantling machines step can be taken to stop catastrophic failures which cause losses due to unforeseen breakdowns.

CeeDey will providing specialised services for infrared thermography inspection, together with a vast range of products and reliability maintenance solution packages.

Infrared Electrical Thermography Survey Benefits

An infrared electrical thermography survey can result in significant financial savings for the client by:

- Reducing the risk of an electrical fire.

- Reducing the risk of an unplanned electrical outage.

- Identifying priorities for planned maintenance, resulting in your spend going where it needed most.

- Determines if the elements and system have been properly installed and are not damaged

- Reduces downtime

- Reduces risk of equipment failure

- Increases safety

- Improves insurability

- Reduces liability exposure of the designers and installers

- Improves system performance

- Determines elements and systems carry out properly and meet the design intent

- Determines if elements and systems compliance with the project specifications and design

- Reduces construction schedule delays

- Saves money